By: Bennie A. Recebido

SORSOGON CITY, April 13 (PIA)

– The Coastal Community Resources (Coastal Core) and Livelihood Development, Inc. in its effort to help increase the fisher

folks’ household income, Coastal Core introduced drying technologies that will

undoubtedly help the fisher folks who chose basket weaving as an alternative to

fishing activities.

Basket weaving is one among

the many livelihoods’ diversification supported by the Coastal Core through a

partnership project called “Convenio” under the Instituto de Promoción y Apoyo al Desarrollo (IPADE) and funded by the Agencia Espanola de Cooperacion Internacional Para El

Desarrollo (AECID).

Coastal Core Project Coordinator

Maila Quiring said that the technology will not only benefit their

project-assisted communities but the basket weavers of the whole Sorsogon as

well.

“Traditional drying process of

screw pines, the primary material used for basket weaving, is dependent to

sunlight. But the weather now is so unpredictable. Effects of changing weather

to basket weavers cannot be impeded. This is why we come up with a climate

change adaptive and hazard resilient drying facilities for handicraft weavers,”

she said.

“Prior to the beginning of the project study,

we conducted comparative study to really come up with best results. We started

by studying the traditional and local

drying practices and tapped the expertise of outside resources in coming up

with a more improved drying technologies. We conducted interfacing and pool

traditional and modern procedures that eventually emerged into hybrid models

with the highest efficiency and cost effectiveness,” Quiring explained.

Through the “Convenio”, five

drying facilities were introduced namely:

1. DRUM TYPE DRYER

·

Plastic box with metal frame ( 1mx1mx2m - height)

·

Aided by charcoal stove as heat source

·

Vertical drying compartment

·

Wrapped in plastics to promote greenhouse effect

·

With exit porthole on top to allow moisture to exit

·

Cost: P7,500.00

·

Life span: 2 years

OBSERVATIONS:

·

Slow drying of leaves. For best result, dry leaves

first in the open before setting inside the dryer for finishing

·

Can be use during rainy season

·

Longer drying time, more fuel consumed

·

Exit funnel should be wider to facilitate/ promote

additional draft of moist air

2.

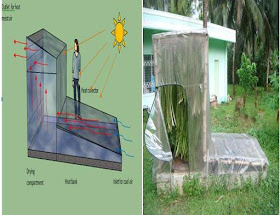

SOLAR DRYER

·

A drying compartment,

·

1.8m x 3.6m, wrapped with plastic and bamboo frame

(green house effect)

·

Heat bank as heat collector made of black &

magnetic sand (margaha)

·

Cost: P9,000.00

·

Life Span: 2 years

OBSERVATIONS:

· Prove the effectiveness of green house and convection current

· Reduced drying period from 4-6 days in the open sun to 1 day in the drying facility

· Good quality of leaves as compared to leaves dried in the open

· Explore bigger design for solar dryer

3.

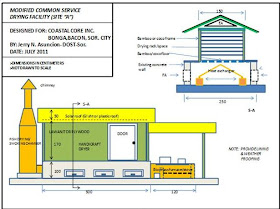

MEDYA TALYE 3 IN 1

DRYER:

·

Semi-concrete drying structure with corrugated

galvanized iron as roofing and plywood as walling.

·

Metal heat exchanger

·

Multiple use : cooking, drying and smoking

·

Capacity: 600-700 leaves

·

Cost: P80,000.00

·

Life Span: 5 years

4.

3 IN 1 SLAB DRYER

·

All concrete drying structure

·

metal heat exchanger

·

Multiple-use: cooking, drying and smoking

·

Capacity: 600-700 leaves

·

Cost: P150,000.00

·

Life Span of 15-20 years

5.

3 IN 1 KITCHEN

DRYER

·

All concrete drying structure.

·

Source of heat: solar heat bank and fuel stove

·

Multiple use : cooking, drying and smoking

·

Cost: P65,000.00

·

Life Span: 15-20 years

The table below shows the efficiency of the the drying technologies designed:

Dryer Type

|

Temp. Inside

|

Temp. Outside

|

Humidity Inside

|

Humidity Outside

|

Efficiency

|

Drum Type Dryer

|

41

|

30

|

45

|

47

|

3.77

|

Solar Dryer

|

39

|

37

|

48

|

48

|

3.14

|

Medya Talye 3 in 1 Dryer

|

40

|

29

|

52

|

57

|

3.59

|

Slab Type 3 in 1

Dryer

|

41

|

30

|

45

|

47

|

3.79

|

Of the five recommended, three

drying technologies have already been tested in at least five coastal barangays

in Bacon District, Sorsogon City. Coastal Core, however leave to the discretion

of the basket weaver, individual or group weavers, the decision which type of

drying technology would they adopt.

Coastal

Core is a non-government organization based in Sorsogon City that work on

resource management, public and policy advocacy, organizing and capacity

building for fisher folks specifically on Community-Based Coastal Resource

Management. (BARecebido, PIA Sorsogon)

No comments:

Post a Comment